Double Stage Foam Crosslinked Foam

Lightweight, Strong, and Versatile

Our Double Stage Foam technology makes Crosslinked Foam lighter and easier to handle without compromising strength. It is ideal for packaging, automotive, appliances, and construction.

Key Differentiating Features

- Won't scratch surfaces

- Lightweight yet durable

- Aesthetic and customizable in color

- Thermoformable and long-lasting

- Flame-retardant and insulating

- Competitively priced

Crosslinked Foam Sheets with Thermofusion

Evacolors' thermofusion process bonds Crosslinked Foam sheets using heat, without adhesives. This allows for seamless joining of sheets with different hardness levels or materials.

Advantages of Thermofused Crosslinked Foam Sheets

- Combine densities from 2LB to 8LB and mix different colors.

- Enhanced strength and durability through molecular bonding, not external agents

- Bond identical or different formulations, enabling versatile applications — e.g., a rigid polyethylene base with a soft EVA cushion

- Achieve custom thicknesses for your project (e.g., join a 10 mm sheet with a 20 mm sheet)

- More cost-effective than using adhesives

- Optimize material usage by fusing leftover sheets to create new, high-quality sheets.

Crosslinked Foam Recycling

Recycled crosslinked foam sheets are made from surplus material from various projects and reintegrated into the manufacturing formula. Instead of relying solely on virgin resin, part of the content is recycled.

This approach allows us to offer recycled final products, which are in growing demand, especially in the automotive industry, while also supporting environmental sustainability.

Currently, we offer a standard recycled product: XLPE-5.5LB-40°. However, at Evacolors, we can manufacture recycled sheets in any density, hardness, or thickness, saving up to 8% in cost, depending on the formula used.

Thermoformed Surface Textures

Stand out in the market with unique, customized surface embossing using our thermoforming process.  Crosslinked Foam is molded to match any design or mold through a precise combination of heat and cooling.

Crosslinked Foam is molded to match any design or mold through a precise combination of heat and cooling.

This is how thermoformed textures are made

1-minute video

We offer three standard embossing patterns, which can be applied to sheets or rolls, depending on minimum order quantities.

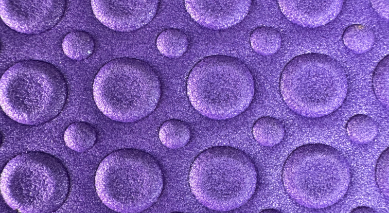

Bubble Pattern

Bubble Pattern

FEATURES

- Provides anti-slip properties

- Deeper texture for greater durability

COMMON USES

- Hotel sandals

- Beach sandals

- Casual sandals

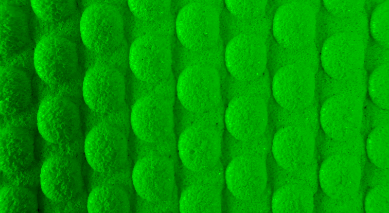

Dot Pattern

Dot Pattern

FEATURES

- Provides anti-slip properties

- Deeper texture for greater durability

USOS MÁS COMUNES

- Hotel sandals

- Beach sandals

- Casual sandals

Star Pattern

Star Pattern

FEATURES

- Provides anti-slip properties

- Shallower texture allows the use of thinner Foam, reducing production costs.

- Helps protect floors from scratches

- Adds a textured visual finish

COMMON USES

- Hotel or party sandals

- Sports gear

- Automotive finishes

- Children's play area flooring